Stair Treads – One Step at a Time

No matter the location, a staircase of any size can be a hazard. According to OSHA (Occupational Safety and Health Administration), slips, trips, and falls constitute most general workplace accidents so it’s extremely important to look closely at stairs and their treads. The “tread” of the stair is the horizontal part of a staircase where people step when climbing up or down. The material chosen for the stair tread will have an impact on the visual look of the staircase as well as the safety. Stair treads come in several styles and materials and can accommodate any kind of foot traffic for staircases both inside and out.

There are a number of factors to consider when selecting the right stair tread, including:

- Indoor or outdoor staircase (nonslip stair treads are usually used outdoors to increase traction)

- Public or private setting

- Heavy, medium, or light foot traffic

- Exposure to water or moisture

Stair Tread Materials to Consider:

Rubber Stair Treads

Rubber stair treads are a solid choice for many installations including commercial, industrial, educational facilities, multi-family housing, offices, retail stores, and healthcare. Easy to clean and maintain, rubber is ideal for heavy traffic and public spaces. Rubber stair treads are also inherently slip resistant and durable. Generally molded of top quality, homogeneous rubber, these stair treads create a lot of traction, which is the amount of frictional force that keeps a shoe from slipping over a surface. With more traction, the possibilities of slip-and-fall accidents are reduced. If your stair treads are exposed to rain or water, textured rubber treads can add even more friction to slippery stairs. In addition, installers find rubber tread products easier to trim on site to the exact size of each step. Tapered nosing ensures a better fit while the smooth rear border allows for easy cleaning and maintenance. In addition, some of the textured rubber stair treads available create a rugged, industrial look which may be appealing in some design schematics.

Of note, Roppe has recently engineered the world’s first rubber stair treads with DuPont™ Kevlar®. From normal wear and tear to downright abuse, Roppe Rubber Stair Treads will resist damage that detracts from the appearance and safety of stairs – not just for a few years, but for decades.

Vinyl Stair Treads

Rubber is extremely popular for stair treads, yet vinyl is always a viable choice. Vinyl stair treads are often manufactured with molded patterns to increase traction and help to reduce slipping. Affordable and easy to maintain, vinyl stair treads offer a long-wearing option. Usually made from a nonporous, abrasion-resistant vinyl, the corrugated surface also helps remove dirt and debris under foot.

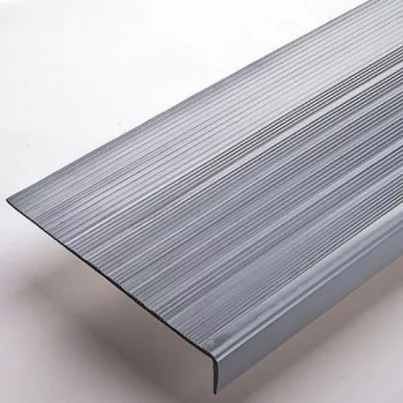

Metal Stair Treads

Metal stair treads are usually made of industrial-grade, heat-treated aluminum, iron, and steel. These stair treads are cast or bonded with long-lasting oxide abrasives to create a rugged option for both indoor/outdoor use. Metal stair treads hold up well in extreme weather conditions and are ideal for heavy traffic but can be more slippery. It’s important to select metal stair treads with a diamond pattern or stair treads that have an abrasive coating. Metal stair treads hold up well in any environment including snow, sleet, or rain. If noise is a factor, metal stairs may create louder results under foot.

Wood Stair Treads

Although wood is not popular for high traffic commercial buildings because of cost and wearability, these stair treads offer a design element of warmth and luxury. Considered a more traditional choice, wood stair treads require a moderate degree of ongoing maintenance. Interior options include natural wood and engineered wood.

Continental Flooring Company, teams with a variety of manufacturers, including Flexco, Roppe, RC Musson, Johnsonite, VPI, Armstrong (AHF), and Burke/Mannington Commercial to offer a full line of offers a variety of commercial stair treads, landing tile, stringers, and riser options. Rubber, vinyl, and metal products are available to meet your project requirements – inside and out. Manufacturers utilize various profile designs and textures along with added features like embedded grit strips to aid with safety and ADA requirements.

Please feel free to contact us for product advice, free samples, assistance in specifications, or to place an order. We welcome contract purchases, formal bids, RFQs or Open Market requirements. One call will do it all!

Contact Us Today!

Call Toll Free 800-825-1221 | Request a Quote

Email: info@continentalflooring.com

Our Segments

- Federal, State, County, and Municipalities

- Healthcare

- Schools, Colleges, and Universities

- Public Housing Authority (PHA)

Continental Flooring has been servicing government agencies since 1979 and continues to be a top flooring and ceiling provider in the public sector.